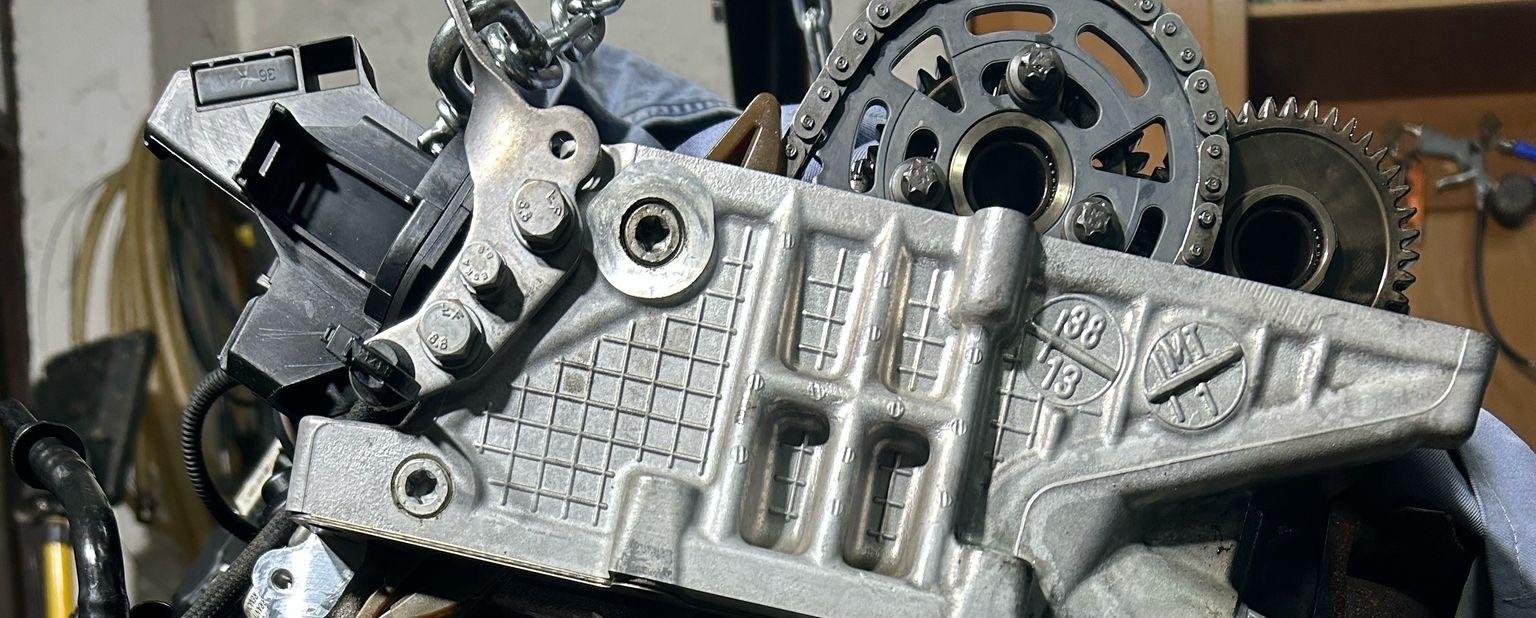

What is a billet engine?

Billet engine is created by machining a solid block of metal into engine parts, such as the block, crankshaft, and cylinder heads. This differs from traditional casting, where molten metal is poured into molds. Billet parts are favored for their superior strength, which helps them handle high stress, making them ideal for racing and performance vehicles.

Billet engines, made from solid blocks of metal like aluminum or steel, are known for their precision, strength, and reliability. These engines are typically used in high-performance sectors, like motorsports, where durability and customization are crucial. However, as manufacturing technology improves and tools become cheaper, the question arises: will billet engines become more popular in the future?

Why Are Billet Engines Popular in Motorsport?

Billet engines are common in motorsports like drag racing, Formula 1, and NASCAR due to their strength and customization potential. Because billet parts are made to precise specifications, they can handle higher forces and temperatures, improving performance. Customization also allows engineers to fine-tune engines for specific applications, giving racers a competitive edge.

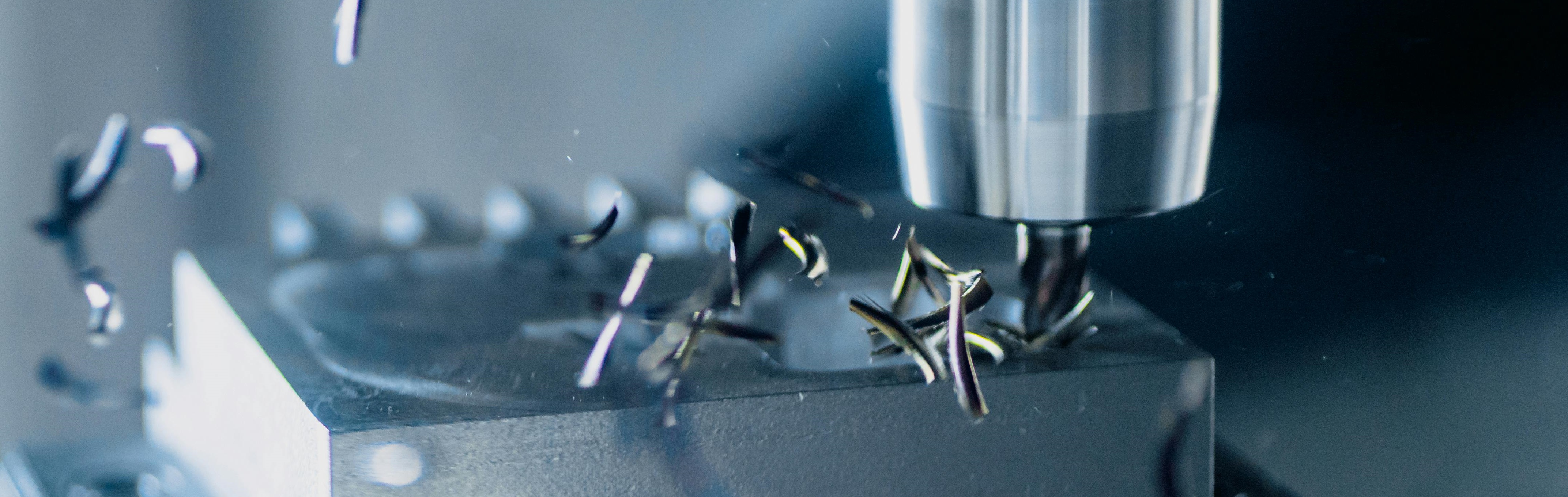

Cheaper Tools and Manufacturing

Historically, building billet engines was expensive due to the cost of high-precision machinery and skilled labor. However, advancements in CNC (Computer Numerical Control) machines and 3D printing have made it more affordable to produce billet components. As these technologies become more accessible, it will lower the overall cost of building billet engines.

Will Billet Engines Become More Common?

-

Cost vs. Benefit: While billet engines are still costly compared to cast engines, the growing affordability of manufacturing tools could make them more accessible in the future. However, for regular vehicles, the cost might still outweigh the benefits.

-

Material Advancements: As new, stronger, and lighter materials are developed, billet engines could become even more attractive for both motorsports and street cars.

-

Customization: Billet engines offer extensive customization, which is increasingly appealing to car enthusiasts who want high-performance, custom stuff. This could drive demand in the custom and performance car markets.

-

Sustainability: Billet parts tend to last longer than cast ones, reducing the need for replacements and waste. If manufacturers adopt greener production methods, billet engines could become more popular, especially in electric vehicles (EVs), which require highly precise, durable components.

Conclusion: A Growing Trend?

Billet engines are unlikely to replace cast engines in everyday vehicles anytime soon, primarily due to cost. However, as tools and manufacturing techniques become cheaper, billet engines could become more common in high-performance cars and custom builds. The future of billet engines looks promising, especially in niches where precision and durability are crucial.